Following an Autodesk Academy tutorial, we were tasked with creating a lamp design which includes a revolving ball joint and textures and showcasing through high quality renders using Fusion360's engine

IFor this Task, I was required to create a lamp following the instructions of an Autodesk Academy educator. This course allowed me to learn more

tools to build upon my knowledge from completing the ergonomics task in year 1. The course was one hour long from start to finish and detailed

all the fundamentals and tips within fusion 360.

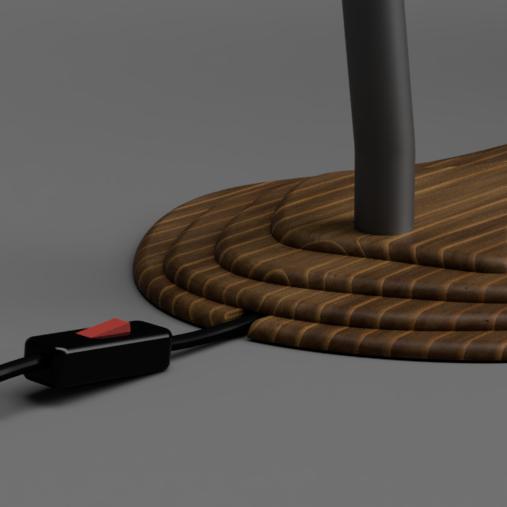

To begin I created the base and arm, learning the different constraints and sketching tips to allow these components to work smoothly. The sweep

tool was my most favourite tool in this section since there’s so many applications it can be used for such as springs, cables, chain links and

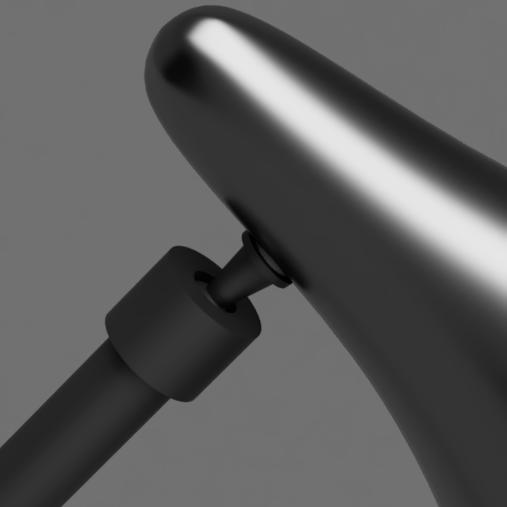

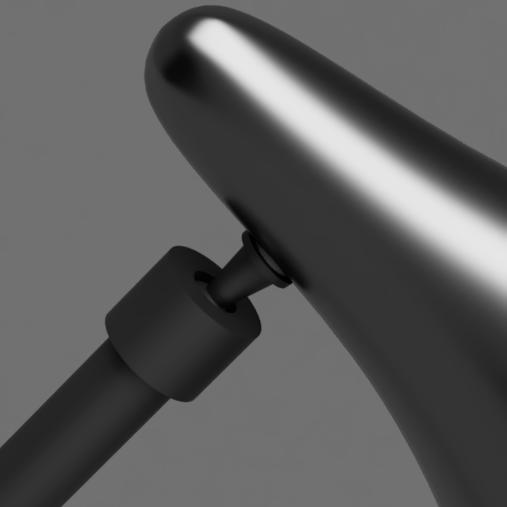

much more. Next, I created the revolving ball joint attached to the arm and allows the head of the lamp to swivel on a 180-degree axis using

different levels of constraints and dynamics. Following on from this, I imported the bulb, attached it to the surface of the ball joint, and

created the shade around the bulb by creating a form and adjusting the individual vertices into position.

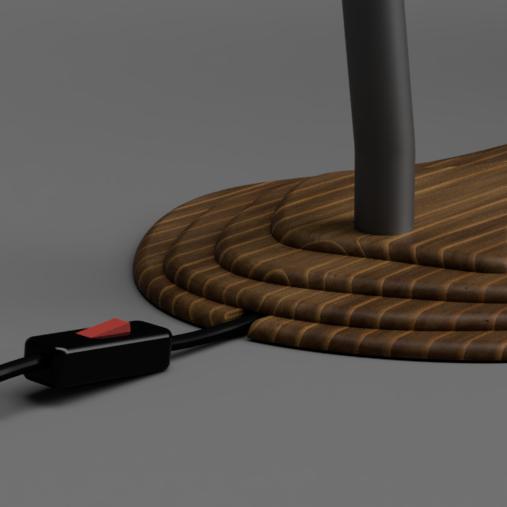

Once the basic modelling was completed, I moved onto applying textures and materials to the object. The overall design and look I wanted to

achieve was a modern, rough grey lamp arm and shade whilst the base aimed to achieve the looks of an OS map and how the contour lines show

the topography of an area. When the contour lines on the map are close this represents a steep gradient similar to what I have tried to

achieve on the rear side of the lamp (where the cable enters). The more space in-between these contour lines indicate a gentle slope as

implemented in the front of the lamp design. I applied a fillet to these edges to round of the sharp contour and help achieve the look I was

going for. I chose the maple wood texture to represent the base of the lamp and an anodised aluminium lamp arm/shade.

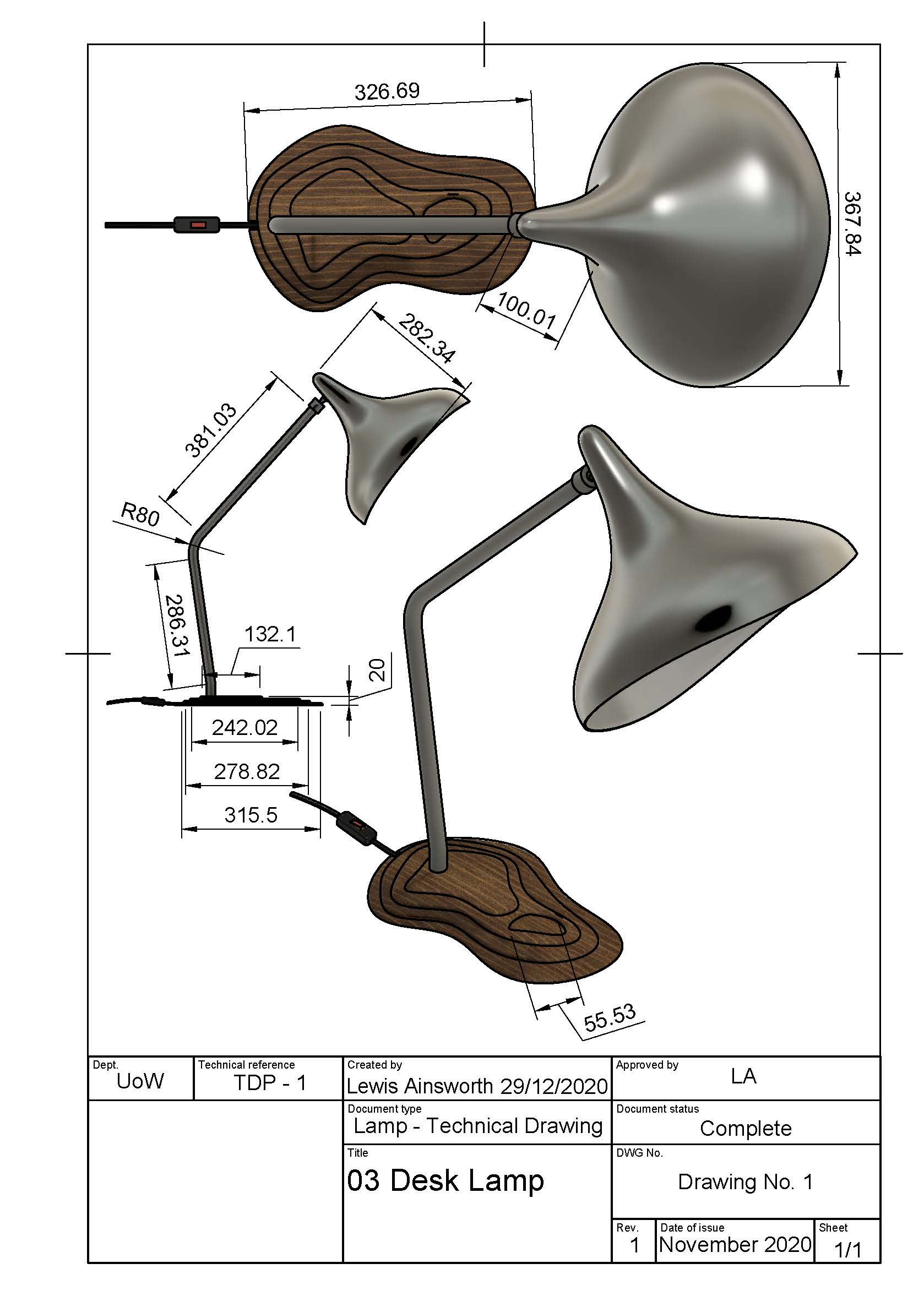

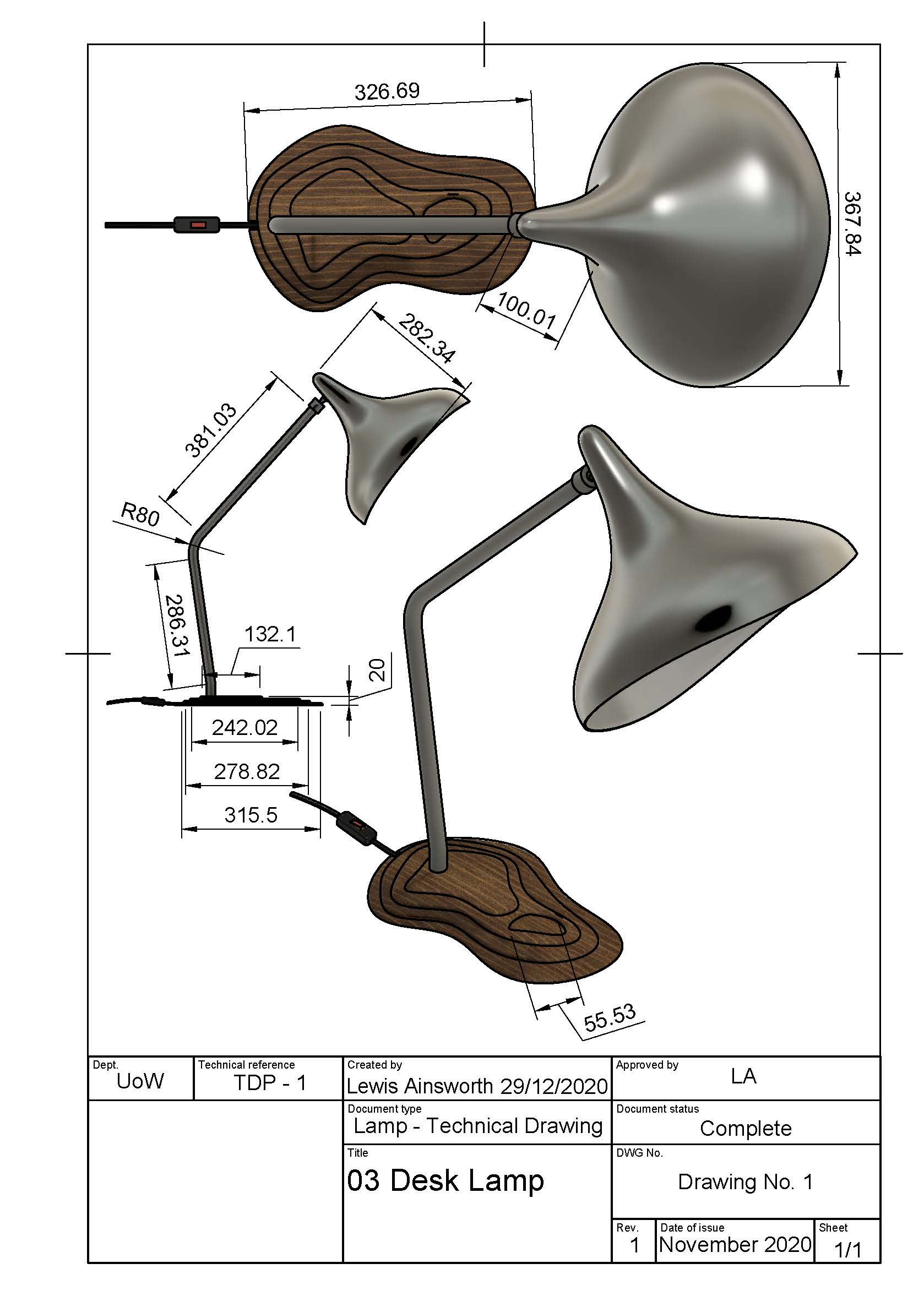

Whilst I queued several views to render, I worked on creating a technical drawing document. Using an A4 template built into Fusion360, I was

able to put together a clear and concise drawing document to understand the shape and size of the product.

See the images below for the final renders and PDF document.