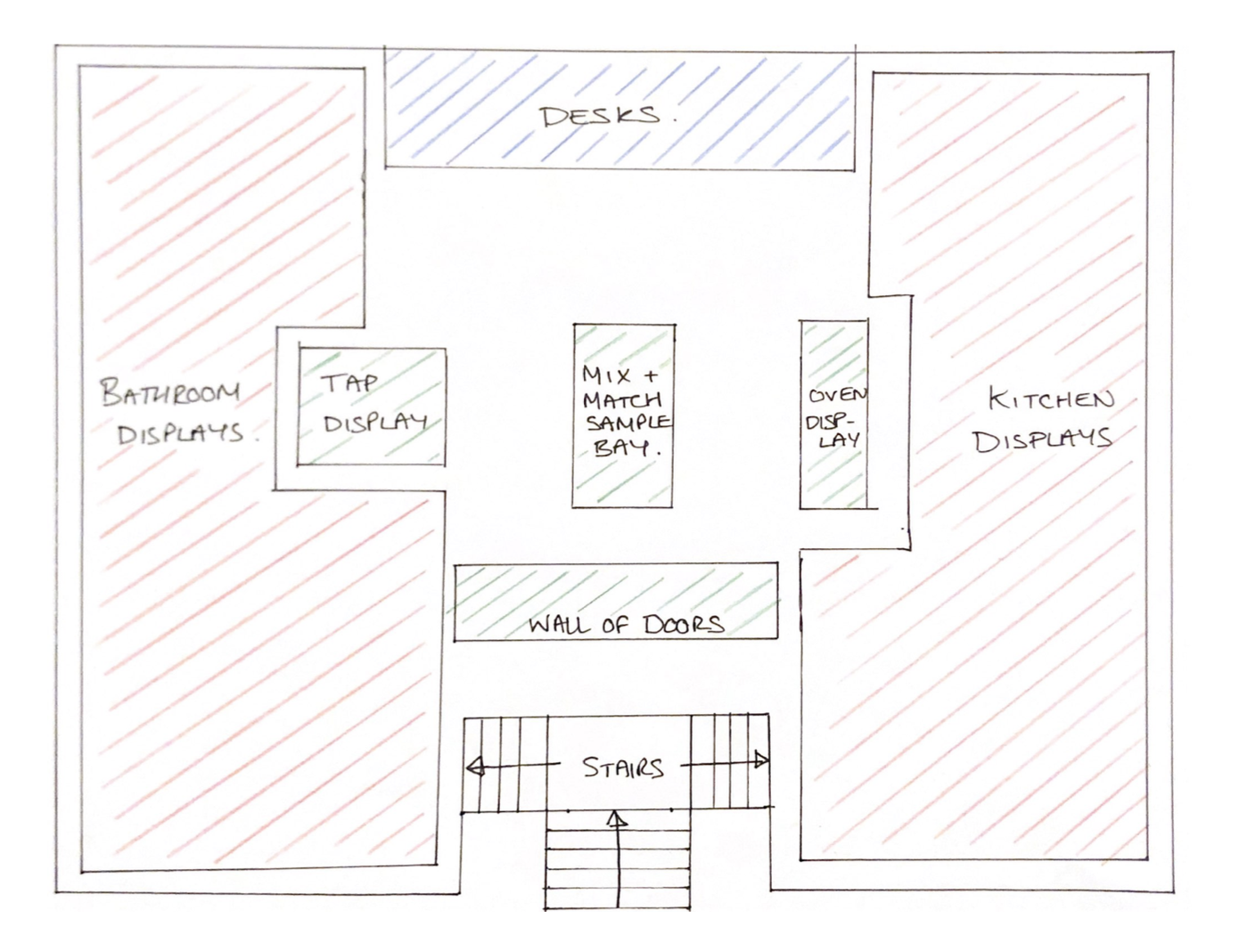

Showroom Layout & Customer Journey:

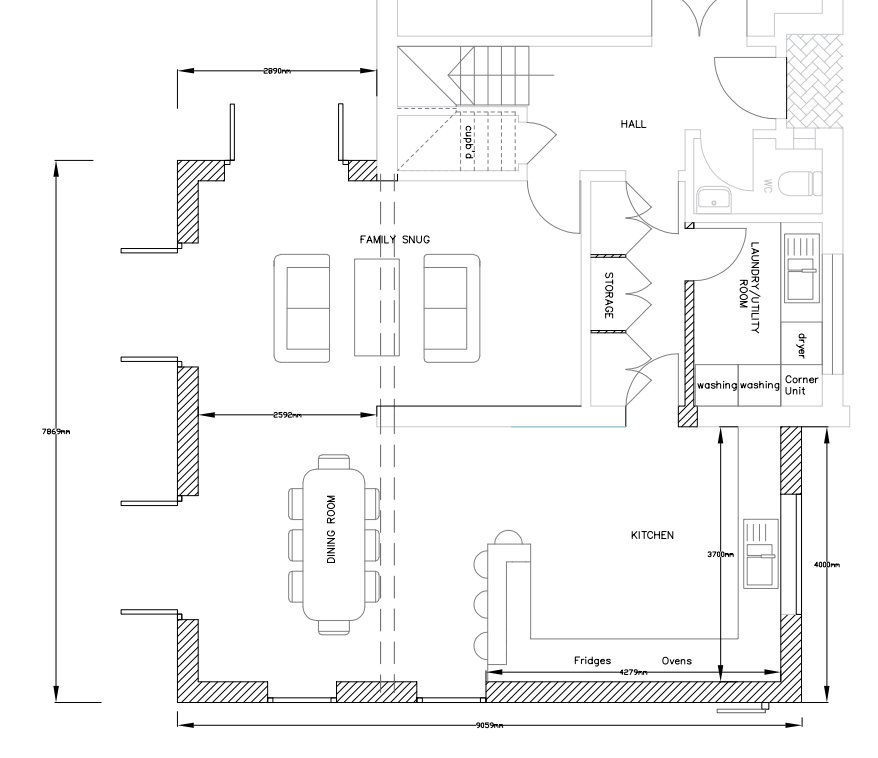

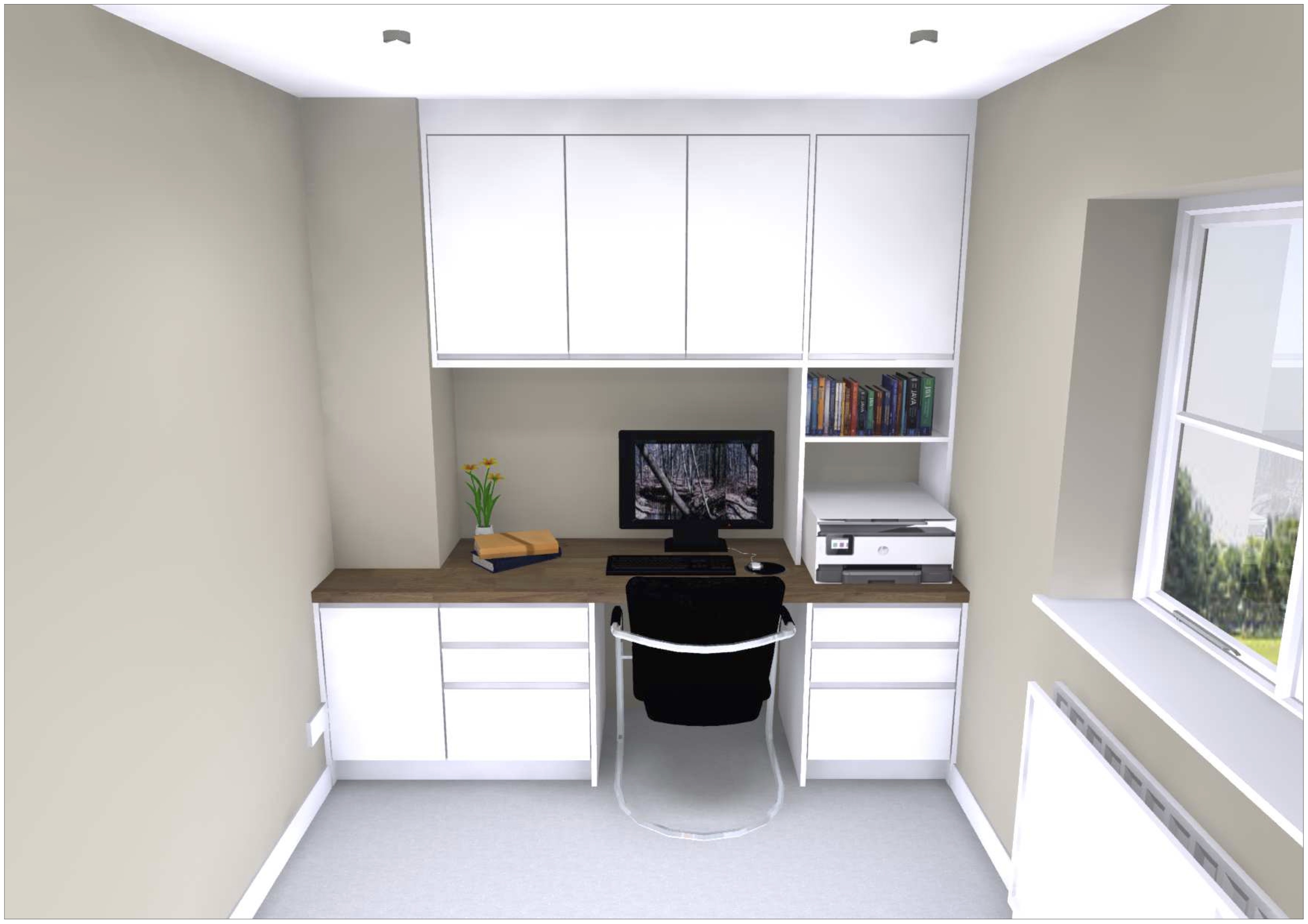

As per last semesters training, I was introduced to the importance of the showroom layout and making sure to utilise the displays wherever possible at both the lead-taking and reveal & close stage. Below is an sketch which shows the layout of the Wickes Winchester showroom which has been cleverly laid out to lead the customer’s straight to the displays which hopefully entices them into the middle after seeing several designs they like. In the sample builder stations, they are able to experiment with the ranges we have to offer and at this point, either the KBA’s or myself will walk up to the customer and talk to them about the products they are trying and the service we offer. In some instances, we often go back to the displays to show them some design features they may have missed and would really like to take forward. Although this stage seems ‘pushy’ it is incredibly important for us to briefly ask if the customer needs our help or would like more information about our products as it plays a vital role in creating an enjoyable customer journey. In several instances, I have been able to design for customers who have said from the start they are impressed with our friendliness and transparency from the start since a few customers have gone to other showrooms such as B&Q and Homebase and are not impressed with the team. Moreover, as a team we make sure to offer tea’s and coffee’s whenever possible to ease the customer and provide a more personal experience as mentioned in my monthly reviews.

The customer journey starts at the moment we talk with the customers. Below lists the steps we use to guide our customers through the process right up to when the installer manages the client:

Lead Taking

Pre-call 1

Home Visit

Designing

Pre-call 2

Reveal & Close Appointment

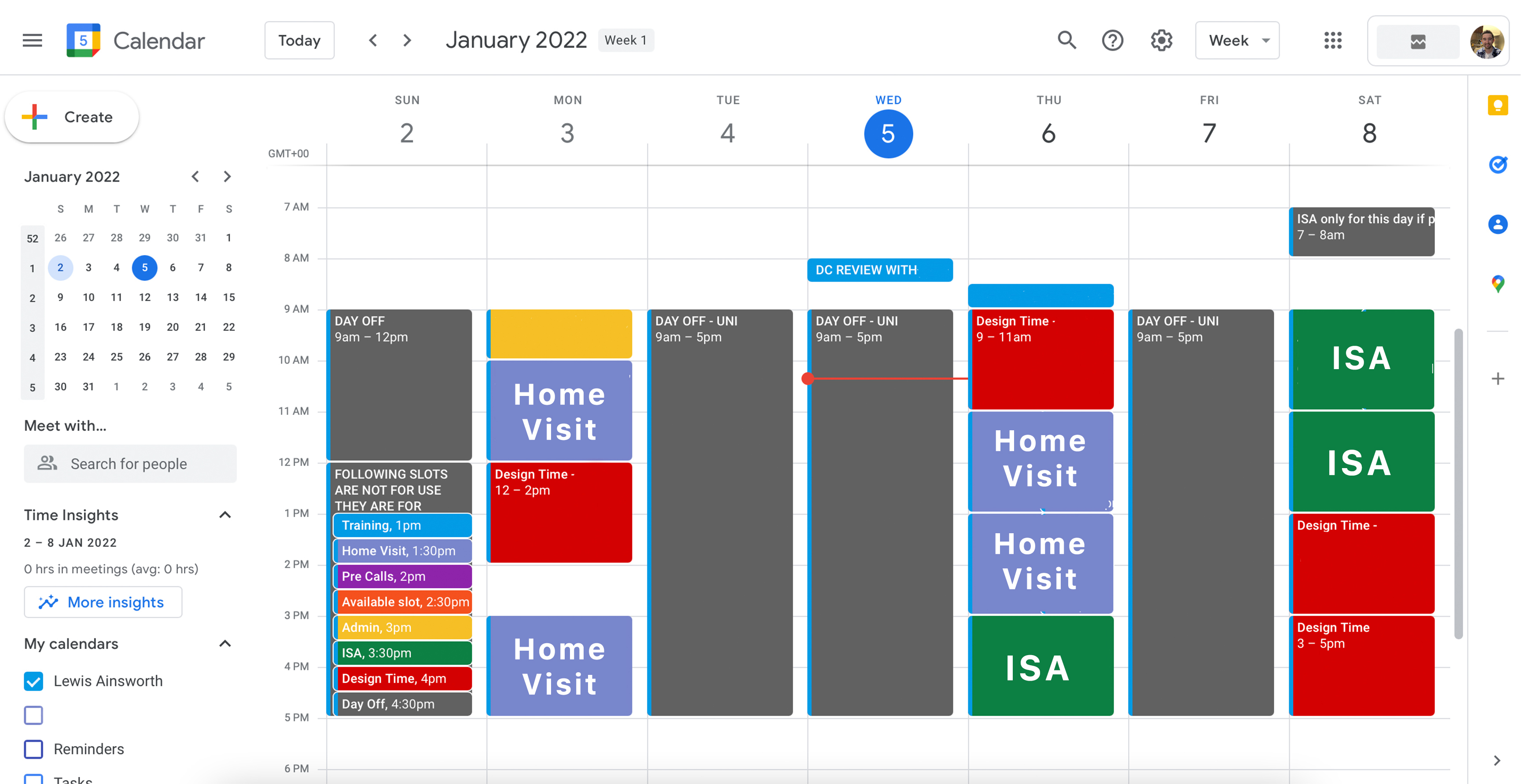

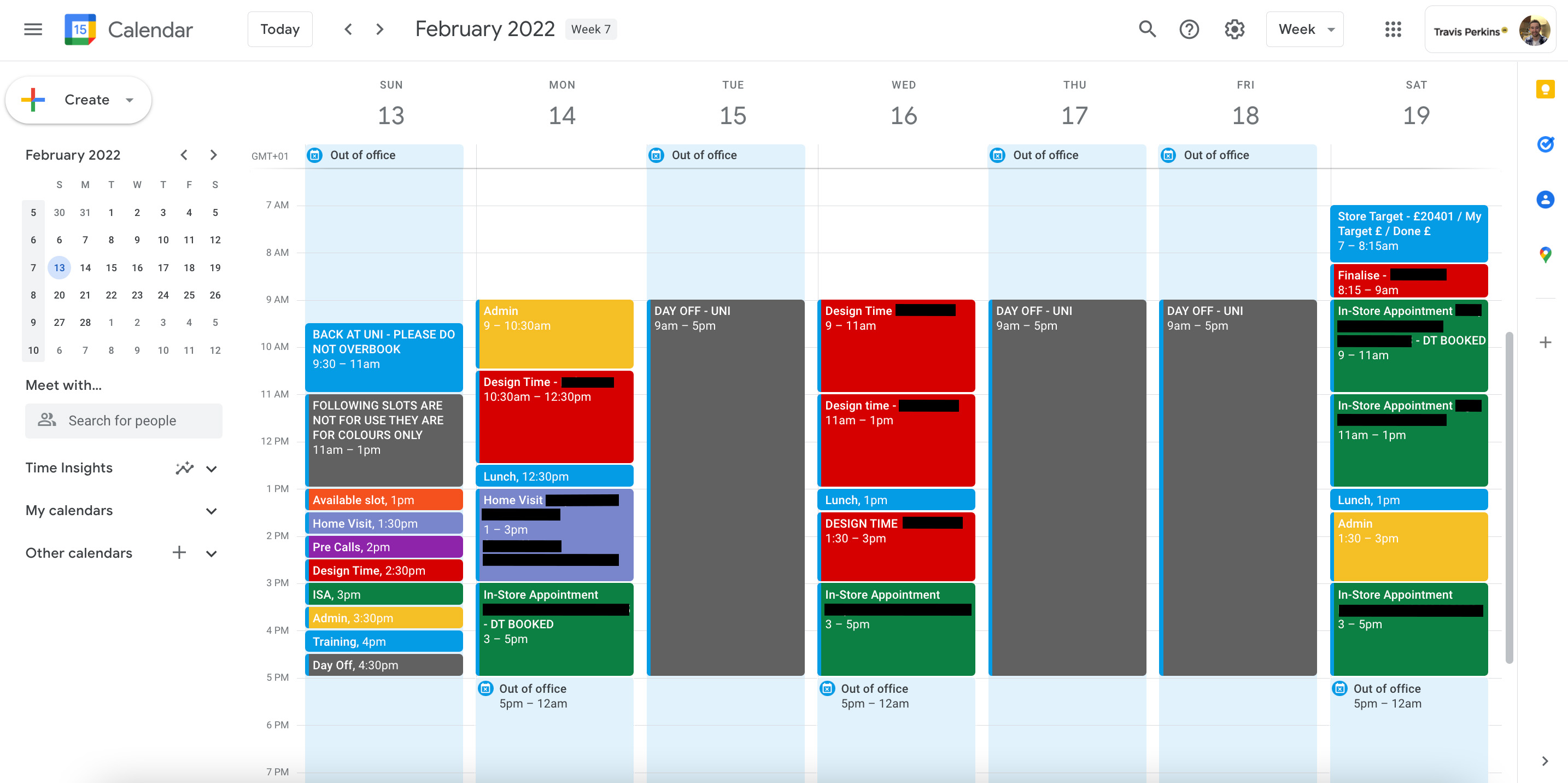

From this journey, DC’s are responsible for the processes between pre-call 1 and the reveal & close appointment but in some instances I like to get involved at the lead-taking stages when I am quiet and help improve my social and customer service skills. Recently, Wickes has demerged from Travis Perkins and has invested a significant amount in a new online, customer logging system known as Zendesk. With my experience I was able to pick up the tools and techniques to log customers on this new system which massively helps visualising each client’s journey and the stage at which they are at. Also, the new system is available as an app which I use on the home visits to take photos and keep under the customer’s profile. I believe this new system has also allowed me to manage my time more effectively and has supported my ability to sell designs with customers since instead of flicking through numerous photos or notes to find the customers profile, there is one place that allows me to see any notes I have created, all the photos I have added but also the customer installation journey and issues that have been raised.